Larkspur

Click on photos to enlarge:

-

Completed kitchen

-

Barn door completed

-

Custom closet completed

-

Low voltage center

-

Hot water heater

-

Deck and railing completed

-

Rear porch railings

-

Stair railings on rear covered porch

-

Downspout modification for better drainage control

-

Crew handling final cleaning details

-

Jim adjusting barn door

-

Wade and Jim bringing in glass barn door

-

Wade installing door hardware

-

Wade installing shelves in custom closet

-

Velux sun tube brings in lots of natural light in primary custom closet

-

New washer and dryer installed

-

Range hood being installed

-

Kitchen cabinet protection has been removed

-

NRG Logic's final inspection

-

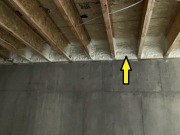

Insulation being installed over concrete walls in unfinished lower level

-

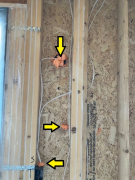

Special washer box adapter to drain attic HVAC equipment

-

Heat pump equipment finalized

-

Extreme temperature heat pump

-

ERV in the insulated mechanical room in the attic

-

Air handler in the insulated mechanical room in the attic

-

Shieko's wave light

-

Kitchen pendant lights over island

-

Ceiling fan in spare bedroom

-

Kitchen faucet

-

Primary vanity countertops with plumbing fixtures & lighting

-

Primary toilet

-

Primary shower valves

-

Electric switches are trimmed

-

Electricians installing switches after house was painted

-

Painter, Maria, getting to the hard spots

-

Plumbing fixtures installed - tub is complete

-

IPE is responsibly harvested to provide a truly renewable resource

-

IPE is naturally resistant to rot & decay. Guaranteed for 20 years without preservatives

-

IPE, an exotic hardwood, tub deck installation in progress

-

Cabinets protection still in place

-

Kitchen tile backsplash

-

Accent tile behind soaking tub

-

Primary bath vanity & top installed

-

Primary shower base

-

Bath #2 grouted & cabinet protection in place

-

Guest shower base

-

Laundry tile floor grouted

-

Solarium tile grouted

-

Kitchen shelves being installed

-

Details of handrail

-

Interior railing in progress

-

Interior railing work in progress

-

Almost to the top

-

Thank goodness for wheels

-

Easy as it goes

-

Shieko helping out the crew

-

Placing on rolling wheels

-

Very heavy - be careful

-

Unloading kitchen countertop

-

Shieko is happy the island countertop is here

-

Upper patio steps & landing

-

Rear patio for study

-

East sidewalk

-

Driveway with protection sign

-

Entry stairs & landing

-

The finishing touch

-

Applying light broom finish

-

Doing the broom finish

-

We got three beating the heat

-

How about this stretch balancing act

-

Creating the expansion joints

-

Starting the driveway finishing

-

Concrete waiting for finish work

-

Now that is team work

-

Three men of a 12-man team finishing the east sidewalk

-

Trowels in action

-

Finishing the edge

-

Finishing the lower patio

-

Finishing the lower patio

-

Finishing the steps

-

Upper patio finish

-

Upper patio finishing work in progress

-

Upper patio details

-

Finish work upper patio steps & landing

-

Finishing upper and lower patios

-

Cleaning the line pump truck

-

Tirzo - Owner, manager and a really good guy

-

An excellent trade partner

-

Deck railing posts are installed

-

Deck is wrapped with Vycor flashing for moisture protection & longer durability

-

Stairs to front porch with steel rebar are formed

-

Stairs to front porch are formed

-

Steel mesh & rebar in back upper patio

-

Steel rebar & mesh in rear studio patio

-

Steel rebar & mesh in east sidewalk

-

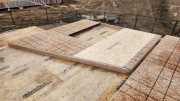

Steel mesh in driveway

-

Back stairs are formed

-

Wetting & compacting road base at rear lower patio

-

Road base under rear patio

-

Back stairs being formed

-

Setting forms

-

Concrete patio staked and string lined

-

Concrete crew preparing east sidewalk

-

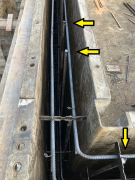

PVC sleeve to take drainage under sidewalk

-

PVC sleeve to take drainage under sidewalk

-

Sidewalk forms set

-

Sleeve location under sidewalk is marked

-

Sleeve location under sidewalk is marked

-

Driveway forms being set

-

Concrete crew preparing driveway

-

Leveling clips are used for all tile installation

-

Laundry room floor tiles

-

Primary bath floor tiles

-

Primary bath tile floor

-

Tile shower base and floor

-

Marcelo applying tile mastic on Schluter shower pan

-

Studio shower niche

-

Pantry shelves

-

Primary closet adjustable shelves

-

Jim drilling for adjustable closet shelf pin

-

Doors, base, & hardwood flooring installed at upper bath

-

Attic access installed in secondary bedroom

-

Closet bulkhead installed

-

Baseboards on hardwood in primary bedroom

-

Jim installing baseboards

-

Stairs covered with protective material

-

Side of open stringer stairs

-

Hardwood stairs are finished and protected

-

Protective floor covering in place

-

Kitchen floor covered with protective material

-

Finished floors are protected

-

Hardwood flooring will be installed at basement landing

-

Piano top layout between solarium & living room

-

Installing hardwood floor in kitchen

-

Protective cabinet material in place

-

Floor & base cabinets are wrapped with innovative reusable material for protection

-

Wall color options

-

Window sills in place

-

Beautiful corner miter with clamp

-

Upper floor doors installed

-

Doors on lower level installed

-

Delivery of doors & interior trim

-

Wood floors installed on upper floor

-

Wood floor in master bedroom

-

Wood flooring acclimating to temperature & humidity

-

Front of house painted

-

Finished front porch beams and soffit

-

Front porch beams finished

-

Exterior paint finished on east side

-

Patio soffit painted

-

Rear of the house painted

-

West side of the house painted

-

Soffits & fascia are painted

-

Prefinished gutter & downspout metal is selected

-

East side beams & brackets being clear sealed

-

Priming exterior siding & trim

-

Caulking & priming

-

Tesla battery controller

-

Tesla battery in the garage

-

Solar panels installed

-

Solarium tiles are installed

-

Tiles in solarium being installed

-

Hallway tiles installed with leveling clips

-

Schulter Ditra mat system in progress-Note the piano shaped radius

-

Installing Schulter Ditra mat in solarium & entry

-

Tub deck waterproofed

-

Tub deck protected with Vycor flashing

-

Vycor on tub deck and corners sealed

-

_thumb.jpg)

Soaking tub prepped for IPE (iron wood decking)

-

IPE wood for tub deck delivered

-

Shower Schluter system waterproofing

-

Shower pan & waterproofing system

-

Tiles delivered

-

Cabinets in studio

-

Bathroom floating cabinets installation in progress

-

Kitchen cabinets installation in progress

-

Range hood chase installed on tall kitchen wall

-

Kitchen cabinets being installed

-

Kitchen cabinets being installed

-

Cabinets delivered and stored in garage

-

Sealing station holds & emits sealant under pressure at 100 PSI

-

Sealing station holds & emits sealant under pressure at 100 PSI

-

Fan and control box for monitoring of aero sealing

-

All penetrations sealed for AeroBarrier sealant application

-

All penetrations sealed for AeroBarrier sealant application

-

All penetrations sealed for AeroBarrier sealant application

-

All penetrations sealed for AeroBarrier sealant application

-

Drywall finishing crew

-

Exterior drywall taped and finish on rear porch ceiling

-

Drywall finished in kitchen

-

Drywall finished in great room

-

Drywall finished in solarium

-

Exterior drywall installed on porch ceiling

-

Exterior grade drywall on rear porch ceiling

-

Front porch exterior grade drywall ceiling

-

Mud applied to openings

-

Drywall finishing in primary bedroom

-

Drywall is taped

-

Tape being applied to ceiling

-

Tape being applied to ceiling

-

Tape application to walls

-

Safety rail post bases ready for install

-

Drywall installed in studio

-

Drywall at loft

-

Drywall in kitchen

-

Drywall crew taping

-

Drywall installed in solarium

-

Installing drywall in studio

-

Installing drywall

-

Installing drywall

-

Installing drywall in garage

-

Protective paper on garage floor

-

Window protective tape being installed

-

Floor protection for a cleaner floor in place

-

Drywall delivered

-

Special plumbing funnel for attic condensate drain

-

Egress cover with ladder and operable access

-

Window well covers are installed

-

Window well covers installed

-

Proper yoke location

-

Interior cover in perfect condition

-

Meter pit cover un-damaged

-

AC condenser line is sealed to foundation

-

Ladder in place for final roof inspection

-

Round retaining wall by solarium

-

Retaining wall at back of house

-

Retaining wall at studio patio

-

Retaining wall on east side for better drainage control

-

Entry retaining walls

-

Retaining walls are build with locking blocks

-

Compaction around retaining walls

-

NW wall ending with boulder

-

Large boulders were moved by tractor

-

Rear retaining wall in progress

-

Small east retaining wall

-

Starting boulder placement for wall around solarium

-

Upper entry retaining wall completed with gravel

-

Lower wall completed

-

Level of blocks filled with gravel

-

Leveling gravel base with bars and granite fines

-

Placing gravel base

-

Gravel for wall base being unloaded

-

Compacting for wall base

-

Compacting for wall base

-

Cutting grade for lower front retaining wall

-

Cutting grade for lower front retaining wall

-

Start of retaining wall excavation

-

Hot cold faucet in garage

-

Additional insulation installed to protect heat ducts

-

Rigid insulation for heat returns behind wall

-

Rigid insulation to be sealed on garage wall

-

Extra insulated lid to protect plumbing drains in garage ceiling

-

Closed cell foam at rim joist between garage & house

-

Closed cell foam in garage wall to house

-

Closed cell foam in garage walls

-

Walls are insulated with 2 inch closed cell foam & blown fiberglass

-

R-60 batt insulation up 8 feet in dining room ceiling

-

R-60 batt insulation in solarium

-

Walls in upper bedroom completed

-

Insulated kitchen wall

-

Walls in kitchen completed

-

Starting fiberglass blown-in insulation in kitchen walls

-

Netting on walls ready for blown-in insulation

-

Netting in primary closet

-

Stapling netting

-

Stapling netting

-

Installing netting protection over skylights

-

Hanging netting for blown-in insulation

-

Attic walls are insulated with spray foam

-

Closed cell foam in walls

-

Closed cell foam in primary bath ceiling and walls

-

Four inches of closed cell foam around skylights and solarium framing

-

Seven inches of closed cell foam up two feet on exterior wall

-

Seven inches of closed cell foam up two feet on exterior wall

-

Seven inches of closed cell foam up two feet of the exterior walls upper attic to baffles

-

Closed cell foam at ledger box sill adjacent to garage wall

-

Headers are insulated with closed cell foam

-

Closed cell foam in door header

-

Closed cell foam in basement ledger

-

Closed cell foam in basement box sills

-

Insulation at return air inlet in family room

-

Windows reveals are framed and shimmed accurately

-

Plumbing in basement for future sink

-

Steel beam pocket is grouted

-

Beam pocket blocked for grouting

-

Vent fan for lower basement floor

-

Crawlspace venting intake pipe

-

Crawlspace venting piping

-

Service lateral connected ready for meter

-

Fire stop foam at exterior outlets

-

Fire stop foam at exterior outlets

-

Tub protected with three-quarter inch plywood lid

-

Soaking tub is installed in the deck

-

Soaking tub being installed

-

Soaking tub is delivered

-

Hardware & handles are installed on sliding doors

-

Sliding doors are shimmed

-

Floor heat registers are protected from dust

-

Bottom plates are caulked for maximum air infiltration control

-

Top plates are caulked

-

Framing is caulked for higher performance tight envelope

-

Framing multipacks are caulked for maximum air infiltration control

-

Hvac ducts are tested and sealed

-

Foam firestopping

-

Wire penetrations are foamed for firestop

-

Wiring above breaker boxes

-

Breaker boxes wall in the garage

-

Electric trench connection in progress

-

Electric meter housing outside of garage

-

400 amp panel being installed

-

Breaker box in garage

-

Electricians setting up the service panel

-

Wiring in kitchen

-

TV wiring in great room

-

Wiring for great room lights

-

Blocks in basement to hold electric outlets past insulation blankets

-

Wall to receive electrical panels in basement

-

Walls are checked with straight edge

-

Studs are shimmed before drywall for perfect wall

-

Pavel is shaving studs with planer for straight walls

-

DenShield used for skylights frame

-

Tub deck protected with Vycor

-

Master tub deck frame

-

DenShield behind tub deck was sealed

-

DenShield installed behind tub deck to hold insulation

-

Caulking in progress to tighten up stud spacing behind tub deck

-

Radon air barrier in upper crawlspace

-

Radon air barrier in upper crawlspace

-

Heating equipment installed in basement

-

Heat pump air handler in basement

-

Basement air handler and duct work

-

Air handler in insulated mechanical room

-

Front of house with roof finished

-

Front of house with siding finished

-

Siding almost complete

-

Vertical siding on west wall

-

Board and batt siding on gables

-

Roofers finishing roofing installation

-

Roofing in progress

-

Basement windows trimmed

-

Hot water lines are insulated

-

Shower valves are installed

-

Master bathroom fan

-

Upper bath fan installed

-

Ceiling cold air return

-

Ceiling heat supply

-

Plumbing, radon and duct below pantry

-

Radon mat system in crawlspace before plastic cover is installed

-

Radon pipe coming from studio crawlspace

-

Radon system below studio

-

Plumbing drain pipes in crawlspace below studio bathroom

-

Attic ducts and main trunks are insulated

-

Insulated ducts above master suite

-

Heat duct below studio

-

Sealed ducts in crawlspace below studio

-

HVAC installers sealing ducts

-

Foam at window gap for air infiltration control

-

Window gaps are filled with foam for air infiltration control

-

Rear of the house with siding finished

-

Siding at entry

-

Siding completed on east side

-

Horizontal siding on west kitchen wall

-

South gables in progress

-

Rear porch gable board and batten completed

-

Rear upper gable with board and batten

-

Siding in progress on rear porch gable

-

Board and batten on solarium gable

-

Garage door installed

-

Corbels below garage cantilever

-

Solarium skylights from inside

-

Solarium skylights installed

-

Skylight flashed and installed

-

Sealed HVAC ducts for maximum airflow from heat pump

-

Sealing duct work for maximum airflow from heat pump

-

Very nice workmanship installing duct work for heat pump

-

We use quiet Panasonic WhisperGreen Select fans

-

Laundry room plumbing

-

Plumbing vents

-

HVAC material stored in great room

-

Best pex water lines and compression fittings

-

Siding being installed

-

Installing siding on east wall

-

We remove brick mold before installing trim

-

Outlet panels with flashing

-

Panels for electric outlets and disconnects

-

Window and trim flashings

-

Window trim

-

Outlet blocks line up with siding lines

-

Special siding placement for electric panel

-

Window wells sealed against foundation

-

Vertical framing with weather barrier sealed to foundation in all similar locations

-

Deck ledger bolted & joist hangers are attached with screws for more secure fastening

-

Garage man door set in sealant

-

Plumbing drain lines in pantry

-

Studio laundry drain and vent line plumbing

-

East soffit with beam and corbels

-

Deck perimeter built with solid glulam beams for extra stability

-

Deck beam is bolted to column for extra strength

-

Front of house

-

Roof shingles delivered

-

Upper bathroom plumbing

-

East soffit beam and supporting corbels

-

Master bedroom deck safety rail in place

-

Deck glulam beams and post

-

Front of house with exterior weather barrier

-

Basement window in window well with Vycor flashing

-

Back patio large sliding door

-

Deck is being built with glulam posts and beams

-

Plumbing drain lines in garage ceiling

-

Plumbing drain lines in studio ceiling

-

Exterior trim and windows

-

East soffit corbels bolted from backside

-

East soffit beam and corbel

-

East soffit glulam beam in place ready for corbel attachments

-

East soffit beam was bolted to each truss

-

East soffit corbels are prebuilt on table

-

Solarium window set in sealant

-

Solarium window to be set in sealant for maximum air infiltration control

-

Installing windows

-

Attic access with tall insulation barrier for cleaner access

-

Attic mechanical room ceiling and walls insulated with closed cell foam

-

Attic mechanical room walls insulated with closed cell foam

-

Basement steel beam shims are welded

-

Steel column welded to steel beam

-

Freshly placed caisson protected from rain

-

Concrete being placed in caisson hole

-

Caisson for deck has dried, steel in place

-

Caisson drill for deck post

-

Caisson staked for drilling to support the upper deck

-

Post straps on side of window openings

-

Attic knee wall extended to 5-inch depth to receive insulation

-

Straps at top of posts for extra strength and stability

-

Fascias at front of house

-

Roof covered with high-quality underlayment-house is dried in

-

Starting house wrap

-

Ice & water shield protected with metal flashing

-

Backings for garage door installation

-

Garage door opening trimmed over Vycor flashing

-

Back of house protected with ice & water shield for future additional moisture control

-

Temp construction safety railings

-

Upper stairs with LVL beams reinforcement for maximum stiffness

-

Basement stairs and walls

-

Window Vycor flashing before windows installation

-

Flashing for extra moisture protection

-

Tyvek & flashing for extra moisture protection

-

Vycor installation for basement windows for additional protection

-

Fascia & soffit insulation in progress

-

Another snow storm. Fascia soffit installation started

-

Master bedroom rake attic wall

-

Attic knee wall above master bedroom

-

Attic walls of mechanical room

-

Attic walls are sheathed to receive insulation

-

Attic knee walls between high and low ceilings

-

Stairs are protected from rain

-

Basement stairs installed

-

Bird mouth stringers

-

Side of stairs are bolted in the side walls for solid feel

-

Each stair stringer is hung on strap

-

Middle stairs with open stringer installed

-

Upper stairs with open stringer installed

-

Steel beam plated

-

View from kitchen to solarium

-

Tall kitchen walls

-

Tall walls blocked 4' O.C. per engineering

-

Rake ceilings by entry

-

Windows in great room bring in lots of natural light

-

Ceiling underframe by entry

-

Front entry

-

Front porch ledger and trusses

-

Front of house

-

Front of house with front porch roof framed

-

Ceiling lines by entry and solarium

-

Stairs delivered

-

View from great room to solarium

-

View from great room thru dining room looking north

-

Attic mechanical room subfloor with access

-

Master bedroom attic knee wall will be insulated

-

Slightly sloped shower seat in upper bathroom

-

Trusses blocked for perfect drywall edge

-

Slightly sloped shower seat in studio

-

Back of the house with roof sheathed

-

Most of the roof is sheathed

-

Gables are permanently braced

-

Gable bracing

-

Rake master bedroom ceiling is under framed

-

Rear patio beams & columns with bracing removed

-

Tall front rake wall being framed

-

18 foot tall kitchen rake wall is framed

-

Front entry wall being sheathed

-

Shape of house with roof trusses installed

-

Rear patio 9x12 glulam beams

-

Strong LVL headers for future barn door in master bedroom

-

Roof gable overhangs (16 O.C.)

-

Roof gable overhangs are supported with 2x6 (16 O.C.)

-

Roof trusses above great room

-

Trusses installed in great room

-

Trusses installed with hurricane clips and roll blocks

-

Future rear patio LVL beams, posts and trusses installed

-

Entry massive glulam posts and beam

-

With roof trusses in place house is getting final shape

-

Cranes placing trusses

-

Crane setting up

-

Crane setting up

-

Walls in place awaiting trusses

-

Garage header straps per engineering

-

Top of upper interior walls with metal straps

-

Strong LVL header for bypass door

-

Top plates of upper interior walls

-

Interior walls on upper floor are framed

-

Interior walls in master suite

-

Epoxy rod and post base for 9x9 post

-

Rear patio 9x9 post are ready to be stood up

-

Patio post bases are epoxied upside-down

-

9x9 patio beams joints are cut and drilled

-

Gable trusses are prepared on the ground

-

Truss gables are sheathed on the ground

-

Glulam posts & beams for rear patio roof are delivered

-

Roof trusses are delivered

-

Roof trusses being dropped off

-

Upper walls in front of the house

-

Wall hold downs are nailed

-

Interior wall plates on third floor

-

Interior wall plates on third floor

-

Walls on third floor

-

Master bedroom rake wall is stood up

-

Walkway built to house for a cleaner & safer job site

-

Master rake wall being stood up

-

Front walls on third floor

-

Long wall on third floor is stood up

-

Mid-level floor walls are stood up

-

Third floor front walls

-

Large exterior walls on mid level are framed & sheathed on floor

-

After snow storm

-

Lots of snow in studio

-

Snow piles behind studio walls

-

Main floor buried in snow

-

Bob removing snow

-

After the big snow storm

-

Master bedroom rake wall is framed

-

Big wall on third floor is framed and sheathed

-

Standing front bedroom wall

-

Standing front bedroom wall

-

Standing front bedroom wall

-

Multi-layer trimmers & posts are built on table for accuracy

-

Bob framing wall on third floor

-

Material is protected from elements

-

Third floor is sheathed

-

Safety railing around stair hole on third floor

-

Temp construction stairs

-

Safety railing around stair hole on second floor

-

Holes in blocks to insulate floor cantilever

-

Studio area is cleaned and braces removed

-

Paul insuring a tight subfloor

-

Bob applying glue for third floor subfloor

-

Paul and Bob laying out subfloor

-

Grading the concrete areas

-

Upper floor LVL beams in place

-

Bob nailing joist hangers above studio

-

Crane placing garage steel beam

-

Crane set up with safety cones

-

Beam hangers are nailed

-

Beam hanger above studio

-

Garage steel beam is plated on ground

-

Interior garage walls are sheathed for easy insulation installation

-

Upper floor material is delivered

-

Garage door is framed

-

Knee walls are braced

-

Pockets for garage steel beam

-

Studio interior walls are framed

-

Massive 4-ply LVL beam above studio

-

Interior walls are connected with strap to keep exterior wall integrity

-

Long 3-ply LVL beam to be raised by crane

-

Walls are perfectly braced per string lines

-

Premium glue under steel beam plate

-

Lines for interior walls

-

Vertical framing foamed to foundation wall

-

Only steel column in basement is installed

-

Studio & garage walls are sheathed

-

Framed and sheathed garage walls

-

Massive posts under garage door header

-

Massive garage door LVL triple header

-

Vycor protection between foundation wall and framing

-

Connection for interior and exterior walls open for insulation

-

Superior LVL headers open for insulation

-

Bob nailing OSB on exterior walls

-

King studs & posts per structural engineer

-

Walls are braced before sheathing

-

Knee walls between studio, basement & main floor

-

Knee walls between garage & main floor

-

Framed pocket for steel beam

-

261Garage walls are framed

-

Exterior walls are stud on foam

-

Advantech flooring installation on main floor complete

-

Advantech flooring being installed on main floor

-

Glue & foam around floor ledgers for superior air infiltration control

-

Foam applied before floor sheet is installed

-

Wall material delivered

-

Spray foam over rigid foam block

-

Rigid foam block behind LVL ledgers

-

Spray foam under rigid foam block

-

Studio floor sheathing is completed

-

Main floor stair hole framed

-

Main floor rim reinforced and squash blocks

-

Main floor roll blocks on top of steel beam

-

Main floor joists are braced

-

Staging area is clean and organized

-

Hangers coated with sealant to prevent floor noise

-

Hangers coated with sealant to prevent floor noise

-

Studio knee wall protected from concrete with Vycor

-

Ample amount of floor adhesive

-

We only use the best floor adhesive

-

Advantech, a superior plywood floor, is used

-

Strong blocks below heavy load points. We see this as very important

-

Roll blocks on top of steel beam

-

Parallel rim boards are reinforced with blocks

-

Floor rim is reinforced for roof loads

-

Crawlspace access is framed

-

Floor joists are braced before sheathing to keep them perfectly straight

-

Floor pack material in the future garage

-

Wall material delivered

-

Small steel beam under studio floor in place

-

Steel beam set in foundation pocket

-

Three bolt pattern of LVL ledgers parallel to joist

-

LVL ledgers bolted with five-eighths bolts

-

Floor joists hangers on LVL ledgers

-

Long steel beam is plated & braced in place

-

Floor material being delivered to future garage

-

Long steel beam lifted by crane

-

Crane to move steel beams

-

LVL treated plates installed in spray foam

-

LVL foundation ledgers protected with Vycor flashing

-

Sill plates installed using foam for superior air infiltration control

-

Superior LVL treated plates for a better framing system

-

Beautiful views from Louisville

-

Paul starting to plate foundation

-

Preparing to place special LVL plates

-

Locating the bolts to drill the plates

-

Plates & ledger lumber delivered after road base installation

-

Steel delivered

-

Chewy's man cleaning the street and sidewalks of the road base

-

Road base in place for staging area for mud-free deliveries

-

Road base in place for staging area for mud-free deliveries

-

Spreading road base

-

Road base for staging area

-

Staging area setup in garage

-

Parking area cleared

-

Paul shoveling snow off garage floor

-

Before snow cleared from parking area

-

Professional organization of SW equipment

-

Installing new clean out risers

-

Shoring for new sewer line

-

New meter pit & yoke

-

New water line under gas line

-

Installing new meter yoke

-

Starting trench for water line

-

Old curb stop riser box

-

Cutting existing abandoned gas line

-

Gas line located before excavation

-

Exposing old curb stop box

-

Debris left from FEMA cleanup

-

Foundation checked with laser & marked

-

Lines snapped for sill plates

-

Lines snapped for sill plates

-

Very minor rough spot removed

-

Final pass on garage floor

-

Concrete finishers for garage floor

-

Basement initial level and finish

-

First layer of concrete completed for garage floor

-

Ready for concrete

-

Access hatch

-

Membrane below structural floor mechanically fastened to the walls

-

Membrane below structural floor mechanically fastened to the walls

-

Rear patio walls complete & ready for backfill

-

Rear patio walls complete & ready for backfill

-

Corrugated steel in place - ready for concrete

-

Corrugated steel in place - ready for concrete

-

Basement ready for concrete

-

Steel mat in place for structural garage floor. Ready for concrete

-

Vapor barrier with sealed joints under garage structural floor

-

Cutting corrugated panels

-

Radon connection basement to crawlspace

-

Radon mat system

-

Crawlspace leveled ready for radon & vapor barrier

-

Cleaned street & sidewalk per city code

-

Cleaned street & sidewalk per city code

-

Welding & painting welded areas garage structural floor

-

Steel beams for garage floor in place

-

Laser level top of wall

-

Rough top of wall gauge

-

Leveling rear wall

-

Using the vibrator to remove bubbles

-

Using the vibrator to remove bubbles

-

Moving concrete in the forms

-

Placing concrete for 2nd phase of rear porch walls

-

Installing 2nd phase of foundation forms

-

Grading backfill at entry

-

Grading backfill at entry

-

Backfill compaction

-

Backfill compaction

-

Drilling in anchor bolts

-

Installing window well

-

Lifting window well off the truck

-

Beautiful finished concrete walls at front & entry

-

Garage & front entry

-

Structural steel floor in basement

-

Structural floor steel in basement

-

Structural floor steel delivered

-

Basement main support beam

-

Beam supports being attached to the foundation wall

-

Beams & support members being welded

-

Checking for void collapse with rebar

-

Spoils cleaned out

-

Spoils from drain left in basement

-

Perimeter drain in garage around basement

-

Drain at northwest corner

-

Drain & riser at basement window

-

Drain and cover at front entry

-

Drain and cover outside crawlspace

-

Sump pit in crawlspace

-

Corrugated steel over sewer pipe outlet

-

Insulation blankets over forms

-

Insulation blankets over forms

-

Concrete & anchor bolts placed

-

Concrete & anchor bolts placed

-

Concrete just placed into forms

-

Leveling & finishing top of foundation

-

Pumping in progress

-

Pump operator using remote control filling forms

-

Pump set up

-

Wall height - 3 feet & 2 inches per plan

-

Vertical steel spacing

-

Vertical #4 at 4 ft OC or less

-

Steel splice well over the minimum 2 feet

-

NW corner wall steel

-

NE corner wall steel epoxied into existing concrete

-

House to porch intersection

-

Corner caisson & wall steel

-

Center wall caisson

-

Bottom 2 - #4 bars above the void

-

Void at the bottom of the wall

-

Void material being delivered

-

Wall reinforcing per engineer design

-

Vertical reinforcing bars

-

Reinforcing per engineered plans

-

Reinforcing per engineered plans

-

Reinforcing over wood window buck

-

Reinforcing details

-

Reinforcing details

-

Reinforcing details

-

Reinforcing details

-

Reinforcing details

-

Forms set & ready to place concrete

-

Final pieces being placed in the forms

-

Reviewing wall heights

-

Exterior forms in place

-

Garage forms

-

Foundation form placements in progress

-

Foundation form placements in progress

-

Form placements in progress

-

Forms being loaded into excavation

-

Intermediate support pads poured in place

-

Caissons & pads with steel

-

All caissons with steel poured in place

-

Corner caisson with support pads

-

Finished caisson top

-

Sonotube in place & finishing at proper elevation

-

Caisson tops covered with insulation & blankets for protection from cold

-

Caisson top before sonotube top set in place to prevent mushrooming

-

Placing concrete into drilled hole

-

Checking caisson elevation

-

Drilled holes with steel in place

-

Cleaning spoils away from the hole

-

Caisson drilling in progress

-

Drilling caissons per soil engineer

-

Excavation complete & caisson locations pinned

-

Excavation complete & caisson locations pinned

-

Caissons left in during demolition

-

Caissons left in during demolition

-

Caissons left in during demolition

-

Soil from excavation stored on adjacent lot

-

Excavation begins

-

Excavation begins

-

Ramp into excavation

-

Lot staked

-

Lot clean by Paul & staking

-

Lot before cleanup

-

Lot staked for soils test

-

Lot staked for soils test

-

_thumb.jpg)

I broke ground! (Loud hurray & applause with gloves on)

-

Ground breaking

-

Maybe not!

-

Maybe!

-

But, let's see if it is for ground breaking of frozen ground

-

It's for digging around flowers & shrubs when the ground is not frozen

-

Oh, it even has instructions

-

Groundbreaking

-

Thank you all for braving the cold & snow

-

What a great group of friends

-

This is John, my builder

|